USED GLASS BOTTLING LINE – 12K B/H KHS 0.33

Glass Bottling Line – 12k b/h KHS 0.33

LINE OVERVIEW

Line Output: 12,000 bph @ 0.33l

Product Bottled: Beer, soft drink

Type of bottle: Glass, 0.5l and 0.33l

Type of cap: Crown cap

Type of labelling machine: “KRONES”, cold glue, 3 labels (front, back and neck)

Type of pasteurizer: Flash pasteurizer

PLC control: Siemens

LINE DETAILS

Depalletizer: KHS 2004 (LOMA)

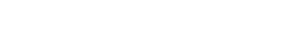

Rinser: KHS 2004 FR-ZM 60-36

Filling Machine: KHS 2004 DMG(SVF)60 + KK(360)10

Bottle conveyors: KHS 2004 BTR

Capper: KHS 2004 NSM MAGNETTECHNK

Filling Inspector: KHS 2004 STRATEC Toshiba P081

Labelling machine: KRONES 1990 3 labels (front, back and neck)

Flash pasteurizer: Schmidt-Rouland 1999

Buffer Tank: Schmidt-Rouland 1999

Tray packer machine “SMI” 2000 17 pack/min, format 3×4

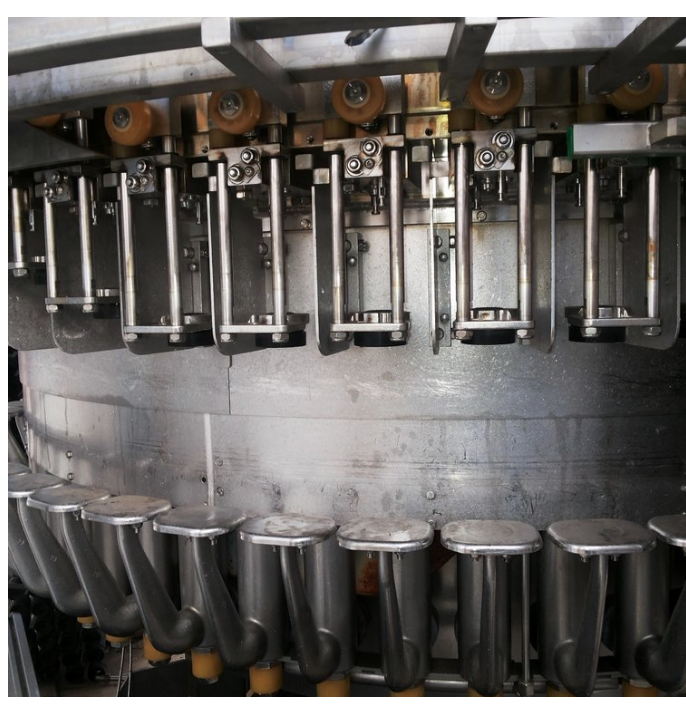

Palletizing Robot Rico 2009

Pallet-Shrink Wrapper Strema 2009

FLASH PASTEURIZER WITH BUFFER TANKS DETAIL

Manufacturer: Schmidt-Rouland

Year: 1999, overhauled in beginning of 2016

Productivity: 40-50 hl / h

Product Designed for: Beer

Pasteurizer: Plate-type

Cooler product: Propylene glycol or ice water

Heating method: Steam

PLC control: “Siemens LOGO”

FUNDAMENTAL PARAMETERS OF PASTEURIZER:

- Inlet temperature of product to pasteurizer: +2°C

- Temperature of beer pasteurization: +72°C-+74°C

- Time of pasteurization: 30 sec

- Outlet temperature or product from pasteurization: +3°C

- Permissible deviations of temperature of the product in the input of the pasteurizer: no more than: ±1ºc;

- Pressure of the product in the input: 3.5-4 bar

- Pressure of air: 6 bar

- Pressure of steam: 2.5-3 bar

- Steam consumption: 300-350 kg/h

- Temperature of steam: +130 ºC-+140 ºC

- Installed power: 8.5kW

- Feeding voltage: 3/N/PE AC 400V 50Hz

- Control voltage: 24V DC

- Security grade: IP 54

PASTEURISER DESCRIPTION:

A three-section plate heat exchanger (made by SCHMIDT, Germany); a tubular keeper; a multigrade, centrifugal pump of high pressure (made in Italy or in Spain)

A heating system containing a steam-water plate heat exchanger (made in Sweden); a centrifugal pump; an electro pneumatic regulation valve (made by Burkert, Germany); a condensate-trap; a controlling regulatory equipment.

A cooling system containing an electro pneumatic regulation valve (made by Burkert, Germany); controlling regulatory equipment.

A control box containing a temperature control equipment (thermo-regulators), as well as buttons to switch on the sensors. Alarm lamps are also included.

Frames, tubular fittings and butterfly manual taps by (AWH, Germany or SODIME, France).

All these systems are installed on one big frame.

After launching the equipment, the set in advance temperature is kept during the whole process of beer pasteurizing. Tap opening and closing is done manually by the operator. In order to preserve the heat exchanger from pressure excess, the pasteurizer is equipped with a pressure relay in addition to an emergency valve and a pneumatic actuator. The pumps are protected with quantity sensors, so whenever the liquid is absent, the pump switch off and the operator is notified about it with the help of the alarm lamps in the control box. If there is no enough air in the machine, it doesn’t launch the process, and the operator is notified about it with the help of the alarm lamps in the control box.

Three-plate heat exchanger consists of pressure plates bearing shaft and clamping screws made of stainless steel AISI 304. intermediate plates exchanger made of stainless steel AISI 316L (steel production in Sweden or Italy).

The tubular fittings and the butterfly manual taps are made of stainless steel AISI 304 or AISI 316L

The tubular keeper is made of tubes (material AISI 304) with a total length provides the performance 50 hl / h and exposure time of 30 seconds.

1.8.1 BUFFER TANK

The buffer tank has a volume of 2,500 litres and working pressure of 3 atm.

The buffer tank consists of:

- a washing head

- a level sensor (3pcs)

- a return pump CIP from the buffer tank with a sensor of liquid quantity

- a valve for remaining pressure

- a vacuum valve

- a CO2 reducer and return valve

PASTEURISER LINE PICTURE AND SCHEMATIC:

GUARANTEE

The refurbishing company provides a 6-month warranty period from the date of commissioning of the equipment.

Price: On request Euros, GBP or USD ex works as is excluding dismantling, packing and loading.

The information provided is for guidance only and the buyer should check all details upon inspecting the line