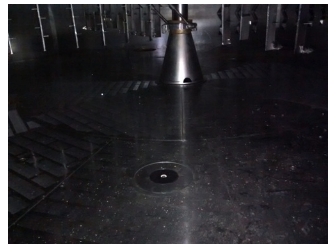

BREWERY 140HL 250,000HL PER YEAR

Reference: 1221A

- Wet mill – 4.2 tons/h – Steinecker

- Water tank – 200hl – Steinecker

- Mash tun – 180 hl – Steinecker

- Lauter tun – 280 hl, insulated, rake and false stainless steel bottom – Steinecker

- Wort kettle – 260 hl, insulated with whirlpool function including outside cooker and vapour condenser – Steinecker

- Wort cooler – Schmitt Bretten

- Spent grain bunker – Schmitt Bretten

- CIP unit – 3 stainless steel tanks, approx 25hl, one tank insulated – Schmitt Bretten

- Pumps and spare parts

FILTER ROOM

2 X KIESELGUHR FILTERS (SCHENK TYPE S45)

- Capacity: 200 hl/h

- Filter area: 40m2

- Pressure: 5 bar

- Vessel volume: 26 hl

KIESELGUHR DOSING UNIT (FILTROX, TYPE SECUROX) – YEAR 1997

- Volume: 219L

- Pressure: 6 bar working pressure

3 X BUFFER TANKS

MALT AREA

Malt Reception, Malt cleaning & Storage (EirichMaschinenfabrik WilhelmSchmitz ) – Capacity 8 tons/h – Vibrator and stone extractor – 4 silos with total capacity 81 tons (3 x 25t and 1 x 6t).

Malt scale, Malt preconditioning, Malt mill (Chronos, Miag, Miag MB14, maintained by Bühler) – Reception scale. 50kg overturning by steam; 6 roller mill Capacity: 1,800 Kg/h

OTHER BREWHOUSE PARTS

3 X YEAST TANKS – ORTMANN KG

- Yeast tank x 3 @ 32 hl

- 2 bar, test pressure 2.6 bar

- H x D 3,330mm x 1,270mm

- Total height including feet 3,905mm

- Each tank cooling jacket.

- One tank additional cooling jacket for cone

- All cooling with ice water or glycol

3 tanks x 30hl, DxH 1,200mm x 2,800mm

1 tank x 25hl fresh water, DxH 1,200mm x 2,800mm

Fittings

Pipework

Cleaning by caustic mixed with water, disinfection by acid and fresh water.

6 X FERMENTATION UNITANKS – ORTMANN KG

- 5 x 935 hl, HxD 10,140mm x 4000mm, total height including feet 11,640mm

- 1 x 480 hl, HxD 10,140mm x 2,700mm total height including feet 11,640mm

- 2 bar, test pressure 2.6 bar

- Each tank 3 cooling jackets including cone

- All cooling ice water or glycol

- 2 cooling pumps

- Includes: 3 beer pumps, temperature control, Dr. Anton tray with desinfection medium for particles, caustic tank pump for the return of cleaning medium,

- Room cooling GK I, Witt: 3 cover cooler, compressor, NH3, type NC 4, pressure: 21.5 bar, to 100°C, content: 42 l NH3, condenser, storage tank

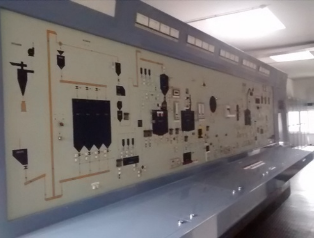

CLEANING IN PLACE (CIP) FOR FV’S – FERTIGUNGSTECHNIK FRIEDRICHSDORF

- 3 tanks x 30hl, DxH 1,200mm x 2,800mm

- 1 tank x 25hl fresh water, DxH 1,200mm x 2,800mm

- Fittings

- Pipework

- Cleaning by caustic mixed with water, disinfection by acid and fresh water

4 X BBTS 200HL – ORTMAN KG

- Year 1982

- Pressure: 2 bar, test pressure 2.6 bar

- Dimensions: HxD 6,846mm x 2,000mm. Including feet 7,196mm

- Each tank is vertical with pipes, panel and fittings

- Single wall

- In cold room

3 X 2000L CIP FOR BBT’S – OTTO MARTIN GLIESSEN

- Year 1991

- Includes acid, caustic and disinfection tanks, they are open top

- Atmospheric pressure

- Cleaning pump flowrate approximately 70 – 100 hl/hr

- The medium runs in circulation

Price: On request Euros ex works as is excluding dismantling, packing and loading.

Information is for guidance only.

The information provided is for guidance only and the buyer should check all details upon inspecting the line