CRAFT BEER BREWERY FULLY AUTOMATED BERAPLAN 60 HL/BREW

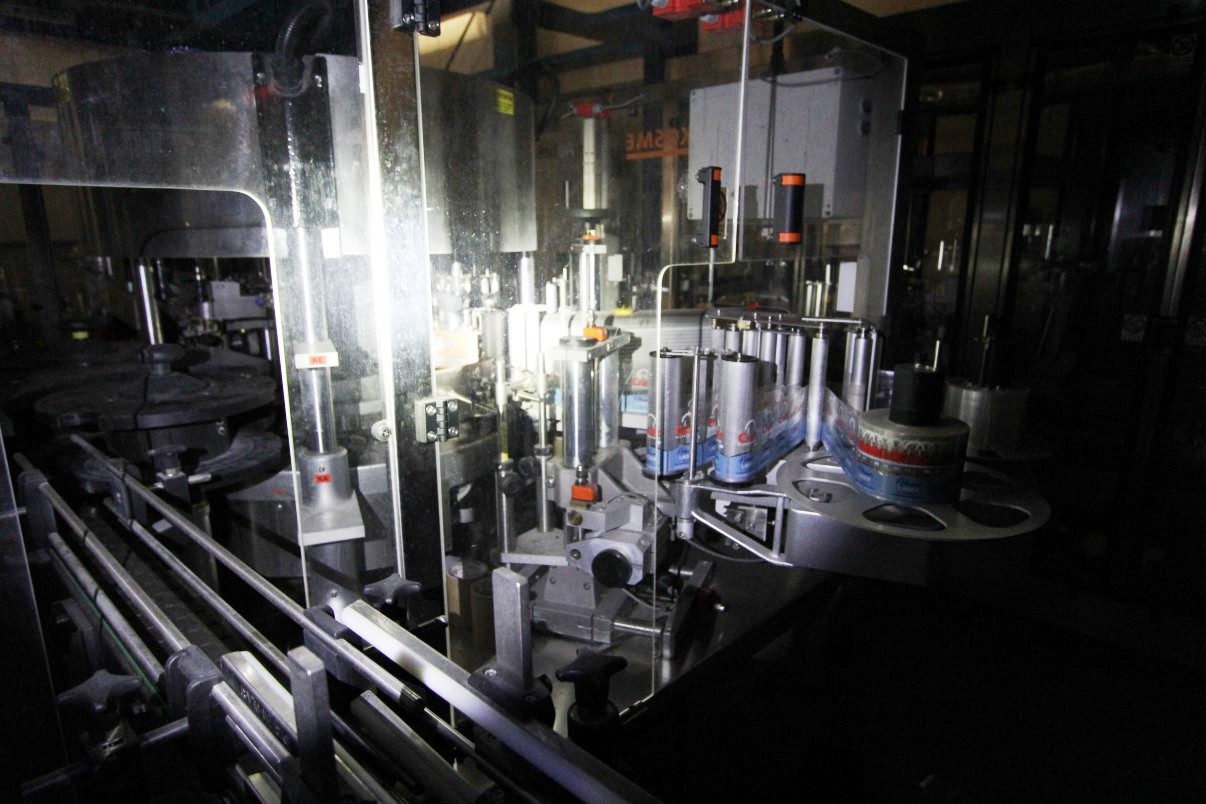

BREWERY LAYOUT:

Price: On request Euros, GBP or USD ex works as is excluding dismantling, packing and loading.

SOLD

BREWERY DESCRIPTION

This is a complete, state of art micro beer brewery capable to produce various type of filtrated and non-filtrated beers at an annual capacity of 30 000 – 35 000 hl and package them in 0.33 and 0.5 litre glassbottles. The brewery was originally made by German BERAPLAN HARTER GmbH in 2002 and it wasextended in 2005 with additional tanks; and again 2008 with complete new Krones (Kosme) one-wayglass line with a capacity of 6500 bph in 0.5 litre bottles packed in a 24 bottle carton box.

The brew line is designed for 60 hl / brew and currently capable to produce 2-3 brews/day. It has onecombined mash & filtration vessel and one boiler vessel with internal boiler build on one stainless steelstructure holding all pipes, pumps and other brew line items and forming one transportable brew line.Whirlpool with worth cooler are built separately as another production block. The line has SiemensSimatic S 7 PLC system and it is operated with PC based central control system.

The tank farm consists of 12 CCT tanks, total net capacity being 3960 hl and 3 bright beer tanks with 463hl total capacity. In addition, there are 4 cooled unitanks with total capacity of 3840 hl for beer storage.

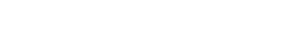

The packaging line was made by Krones in 2008 and operation started in 2009. The line is complete witha fully automated depalletizer, rinser-filler-capper tri block, labeller and carton boxing robot. Palletizingis by manual operation. The line capacity is 6500 bph and it is controlled by Siemens Simatic S7 PLCsystem.

The overall capacity is capable to be increased to 50 000 – 60 000 hl/ annum by adding another mash &filtration vessel (will allow 4-5 brews/day) and possibly some CCTs. The filling line capacity can be increased to 10 000 bph by changing to a faster labeller and adding an automated palletizer.

LIST OF EQUIPMENT:

BREW LINE MADE BY BERAPLAN

1. Malt unloading station from 1000 kg sacks with pneumatic transport system

2. Dry malt mill Kunzei

3. Combined Mash & Lauter tank, capacity 60 hl net

4. Boiler tank with internal boiler, capacity 60 hl net

5. Whirlpool, capacity 60 hl net

6. Wort cooler Alfa Laval

7. Stainless steel spent grain silo 13 m3 with discharge screw

YEAST DEPARTMENT AND FILTRATION EQUIPMENT

1. Beraplan Combined yeast propagator and yeast tank 12 hl

2. Della Toffola beer filter with PVPP candle filter type NF 8

3. Beraplan CIP line with 5 x 1000 litre tanks

CCTS

1. 6 x 240 hl net Beraplan 2002, insulated and with inbuilt cooling system (glycol-water solution)

2. 3 x 360 hl net Grinox 2005, insulated and with inbuilt cooling system (glycol – water solution)

3. 3 x 480 hl net Grinox 2007, insulated and with inbuilt cooling system (glycol – water solution)

OTHER TANKS

1. Unitanks 4 x 960 hl tanks outdoor installation

2. Hot water tank 10 m3 indoor installation

KRONES FILLING LINE 6500 BPH

1. Depalletizer EURODEPACK

2. Empty bottle conveyor system to rinser

3. Alfa Laval flash pasteurizer

4. Krones 3 block filler ISOBLOCK 32-32-8 with 32 filling heads and 8 capping stations

5. FT bottle filling inspector

6. Full bottle conveyors to Kosme bottle dryer

7. Kosme bottle dryer type AIR 3000

8. Kosme Extra Adhesive type 720 with 6 bottle holding plates and 3 labelling stations

9. Kosme Carton box machine with hot glue system