KRONES 72 000 CPH FILLING LINE FOR BEER AND CSD IN ALUMINIUM CANS

Krones 72 000 cph Filling Line for beer and CSD in Aluminium Cans

Complete line except secondary packaging, all equipment is in good condition and immediately available for relocation. The line was delivered in year 2003 by Krones and it was in operation till 2016. Currently the equipment is installed and power and in normal operation condition.

Location: United Kingdom

MAIN CHARACTERISTICS:

- Capacity 72.000 bph at 0.440 liter cans

- Made by Krones in year 2003, in operation till 2016, still installed

- 275, 330, 440, 500 and 568 ml aluminium cans

- Widget (liquid nitrogen) injection

- Operation controls made with Siemens Simatic S7 PLC system

LIST OF MAIN EQUIPMENT:

1. Empty can pallet transport conveyor system, Kettner

2. Empty can pallet depalletiser Kettner Pressant Universal

- Layer interleave removal device, Kettner

- Empty pallet transport conveyor system, capacity max 200 pallets/h

- Empty pallet stacking device, Empty Pallet Storage Magazine, max 100 pallets/h

3. Empty can transport conveyors (mass flow), Krones

4. Minimum pressure single filing device, Krones

5. Empty can transport conveyors (single file) incl. reject system, Krones

6. Empty can rinser (ionised air), Trans-Tech Hysek, type CANJET-S 4900, output 72.000 cph in275 – 568 ml cans with can twist change parts for all size

7. Empty can inspector Krones Cantronic, type LDI

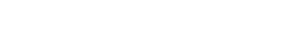

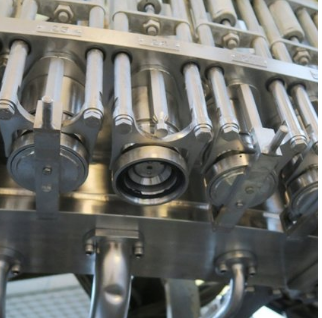

8. Can filler/seamer monoblock with touch screen panel

- Filler Krones VOC-C-125-090-VO volumetric filler with 125 filling valves, machine pitch 3600 and pitch 90,5 mm

- Seamer Ferrum F812 with 12 seaming heads and one lid feeding line. Equipment with liquidnitrogen dosing unit Terboven type ISTE-CON

- Process valve block with buffer tank

9. Can lid unwrapping and feeding system, single line CSW Deventer

10. Full can transport conveyor system (filler – pasteurizer, single file), Krones

11. Can filling lever inspector (pre-pasteurizer) Krones Checkmat type 707

12. Full can pressure inspector (for Widget pre pasteurizer) TapTone 500

13. Full can transport conveyor system (filler – pasteurizer, mass flow), Krones

14. Tunnel pasteurizer, Sander Hansen, Type PC 15.6-504-22.

- Two decks, 8 zones of which 4 for pasteurizing and 4 for regeneration

- Intralox modular plastic conveyor belt, raised rib, series 400

- Process area 152.3 m2.

15. Full can transport conveyor system (pasteurizer – can deceleration device), Krones

16. Two can air driers made by Air Control Industries

17. Two can coding/inspection devices, Videojet/ Sencon, and Videojet EXCEL 170i

18. Can filling level inspector (post-pasteurizer), Krones Checkmat type 707

19. Full can pressure inspector (for Widget post-pasteurizer), TapTone 500

20. Full can transport conveyors

21. Can package date coding system

22. MultiDivirer for packages

23. Palletizer Kettner Pressant Universal AJ with pallet magazine and conveyor system

24. Related electrical panels and MCCs

Price: On request Euros, GBP or USD ex works as is excluding dismantling, packing and loading.

The information provided is for guidance only and the buyer should check all details upon inspecting the line